Clever Uses of Zippers

1. Notice to Customers using Metal Fasteners

Thank you for using YKK products. Nowadays, YKK products are used in a variety of applications, where they are finished in different processes, using various chemicals. This notice is to inform you that discoloration of elements of metal fasteners (golden-brass , yellow-brass, nickel-silver) or transfer of stains onto fabric may occur, depending on the chemicals used.

2. Discoloration of Metal Fasteners

It is well known that copper alloy (brass) will tarnish or discolor through reaction of chemicals such as acids, alkalis, oxidizing agents and reducing agents. If these chemicals remain in adjacent fabrics, they may react with the metal of elements, sliders, or top & bottom stops of fasteners. Heat and moisture hasten chemical reactions, so discoloration will be more likely to occur when products are stored for a long time in plastic bags, especially after steam pressing. Reactive dyes and sulfur dyes, in particular, may react easily with copper alloy causing discoloration.1) Discoloration of metal fasteners attached to wet-processed woolen or cotton fabrics.

Discoloration of metal fasteners can be caused by:

1. Oxidation bleaching (e.g. hydrogen peroxide bleach)

2. Reduction bleaching (e.g. hydrosulfite bleach)

3. Shrink-resistant chlorination finishing (e.g. chlorine oxidation)

After these treatments, if rinsing or neutralization is incomplete, gases (ex. chlorine gas or sulfur dioxide) may be produced or residual chemicals remain in the fabric. Gases or chemicals can react directly with copper alloy in the presence of moisture. Discoloration of elements, sliders or top & bottom stops of fasteners may be caused by these gases or chemicals in fabric when stored in bags soon after pressing.

※ Countermeasures

Use fabrics which are rinsed thoroughly and dried well.

Allow sufficient time between pressing and packing.

2) Discoloration of fasteners attached to leather goods.

Residual chemicals in leather goods may cause discoloration. A variety of chemicals is used in the processing and tanning of leather, including mineral acids, such as sulfuric acid, chromium salts, tannins and aldehydes. It can be difficult to remove completely all the chemicals that have penetrated the animal proteins that make up leather. Residual chemicals in leather, in direct contact with metal fasteners, may cause discoloration over time, particularly in moist conditions.

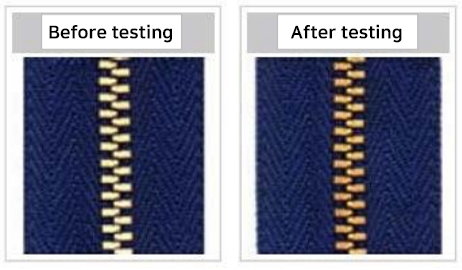

Tarnishing of elements (Heat•Moisture 72h)

※ Countermeasures

Use materials which are rinsed and neutralized thoroughly after leather tanning.

3. Staining and Discoloration of Fabrics

1) Staining of fabrics due to residual chemicals

Chemical substances such as acids or oxidizing substances remaining in fabrics, or used as process chemicals can react with oxidized metal fasteners (GKB, GK). There is also the risk of fabric staining during storage, due to residual chemicals. White or light colored fabrics will be stained more readily.

※ Countermeasures

Use materials and fabrics which are rinsed thoroughly and dried well after each treatment process.

2) Transfer of paraffin wax to fabrics

Elements of metal fasteners are coated with paraffin wax for smooth operation. Paraffin wax will melt when ironed and may stain adjacent fabric.

※ Countermeasures

Press with a cloth or card to protect the area where fasteners are attached.

3) Discoloration of textile goods dyed by reactive dye

Reactive dyes used for piece-dyeing of textile goods mainly made of cotton, may be adversely affected by copper ions. The fabric in contact with brass zipper components may become discolored in humid conditions.

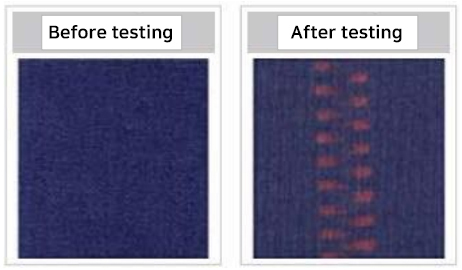

Discoloration of Fabric in contact with Brass Elements (Heat•Moisture 72h)

※ Countermeasures

Piece-dyed textile goods should be stored in dry places with good air circulation after drying thoroughly. Do not store them in airtight plastic bags.

Do not display textile goods in humid places.

※ CAUTION

As the above discoloration is caused by many factors, products should be processed with caution. Adequate rinsing and drying are necessary in each case. Appropriate tests should be performed before bulk use and beware of discoloration of fasteners and discoloration or staining of fabrics when piece-dyeing. YKK has been carried out research and development of fasteners to reduce harm to your goods. However, attention to the above recommendations is requested to avoid these problems. Thank you for your kind understanding.